At Cloud Enclosure Systems

Quality Assurance

To Quality

Our Commitment

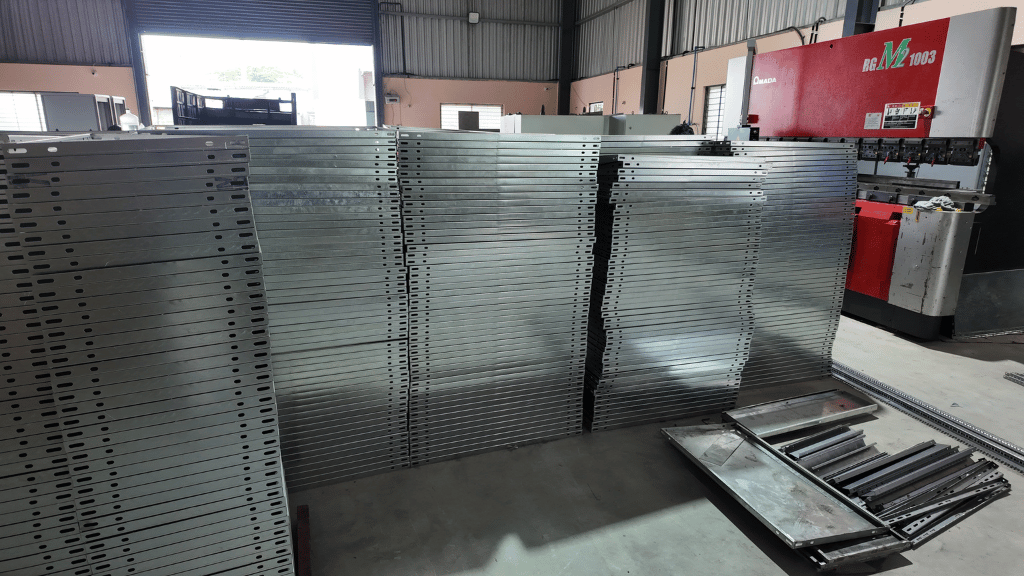

Every product we design and manufacture is backed by a robust quality assurance process. From raw material inspection to final testing, our procedures are engineered to eliminate defects and exceed client expectations.

We follow a zero-compromise approach in:

-

Material selection (Aluminium, Mild Steel, Stainless Steel)

-

Dimensional accuracy and finish

-

IP-rated protection (IP55/IP66)

-

EMI/EMC shielding standards

-

Environmental resistance and durability

Material Inspection

Incoming raw materials are tested for quality and specification compliance.

In-Process Checks

Continuous monitoring during fabrication, welding, machining, and assembly.

Customer Satisfaction

Continuous Improvement

At Cloud Enclosure Systems, customer satisfaction is at the core of everything we do. We are committed to delivering defect-free products on time, every time. Our team ensures transparent communication throughout each project, keeping clients informed and involved at every stage. Beyond delivery, we offer responsive post-sales support and service, reinforcing our promise of reliability, accountability, and long-term partnership.

-

Regular training for quality and production teams

-

Investment in precision machinery and testing equipment

-

Prototyping and pre-delivery validation for custom projects

it’s a Process

Innovation

We believe in innovation and evolution. Through feedback-driven improvement and ongoing training, our team continually upgrades tools, techniques, and product designs.

-

Visual & Dimensional Testing – Final verification for fit, finish, and form.

-

Functional Testing – IP rating tests, door alignment, cable entry checks, load bearing, and more.

-

Packaging & Dispatch – Safe and standardized packing for transit without damage.

Contact

Byraveshwara Industrial Estate, Andrahalli Main Road, Bengaluru-560 091

+91 63600 41320